The chocolate depositing is a process which is there in the industry for a long time. The types and varieties of chocolate products available in the market have a long history of innovation to tell. The chocolate depositor machine is such an idea that improved the way chocolate production happens. Today from large scale chocolate plants to small home-based industries, have chocolate depositing machines to make better tasting products. Let us look at the process of modern chocolate depositors in depth.

The Use

The chocolate depositing machine used today serves a variety of applications. Almost every chocolate available in the market today have some chocolate depositing done to them.

The most common use of these machines includes:

- Filling of different molds or shells with chocolate

- Creating different chocolate shapes, designs, and patterns.

- The machine also helps in improving the chocolate quality and taste.

There are more uses in different industrial scenarios. However, in total, these machines can save a lot of time, energy, and money spends on production. The use of this machine also ensures high-quality products with better taste.

The Process

The chocolate products made through the depositing system have to go through various stages before reaching to packing. The levels of production in a chocolate depositing machine include:

- The preparation: Before the final switch to start the depositor gets on, there are some preparations to be done. The steps in this level mainly include ensuring everything is ready. You should set the temperature, add chocolate to the mass tank, and ensure the availability of shells or molds in the conveyer.

- Switching on: All it wants you to do is switching on the power in this stage. The machines available today are highly automated and can perform with minimal human intervention. Once you power on the device, it will move the chocolate from the tank to a heating chamber. Simultaneously, the shells will start moving through the conveyor system.

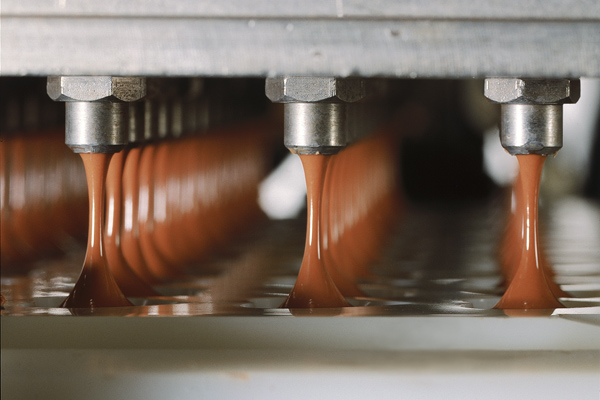

- The depositing part: This is where the actual process kick starts. There will be nozzles pointing to the conveyor. The nozzles have direct connecting with the heating chamber. A consistent amount of liquid chocolate gets passed to the injectors and which in turn fills the shells.

- Cooling of the final product: The chocolate product will have a liquid form of chocolate because of heating. The final product is sent to a cooling unit and kept there for a specific amount of time as required. The cooling help in solidifying the liquid chocolate that got deposited. Once the cooling, the product moves out for quality checks and final packing.